| Availability: | |

|---|---|

| Quantity: | |

Features

• Stamping is used to replace hot forging and die-casting processes, which greatly improves production efficiency, reduces energy consumption and costs, and ensures stable and reliable quality;

• Unique process design prevents bending cracks and stress concentration;

• Square hole design with corresponding square neck bolts for quick and easy installation;

• Meets the friction requirements of GB7588-2020 standard

Application

• Fix the elevator car on the guide rail to prevent the car from shaking or derailing

Material, coating | Electrogalvanizing, |

Hole settings | Square hole/hexagon head bolt |

Certification/Test Report | Pass the friction/clamping force test |

Quality Inspection | Pass |

Product Origin | Songjiang District, Shanghai |

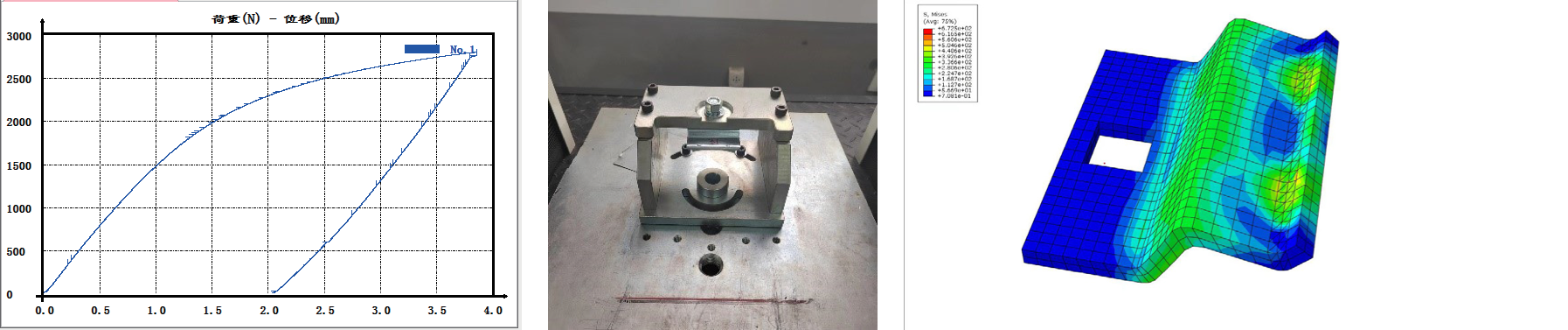

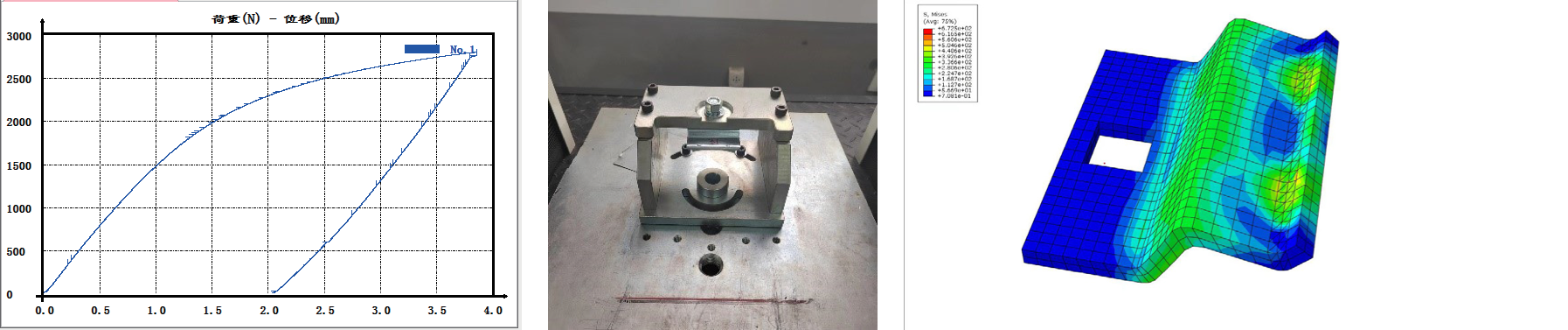

1. Friction test

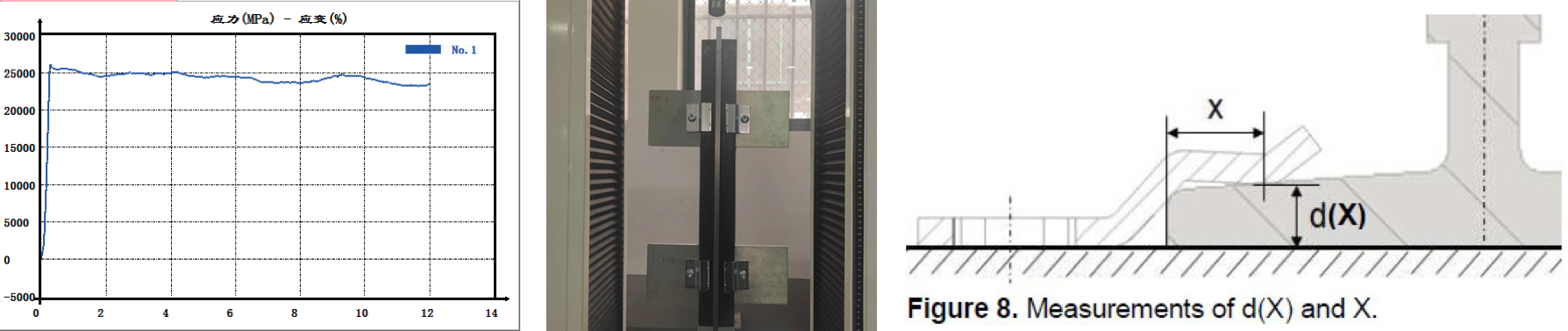

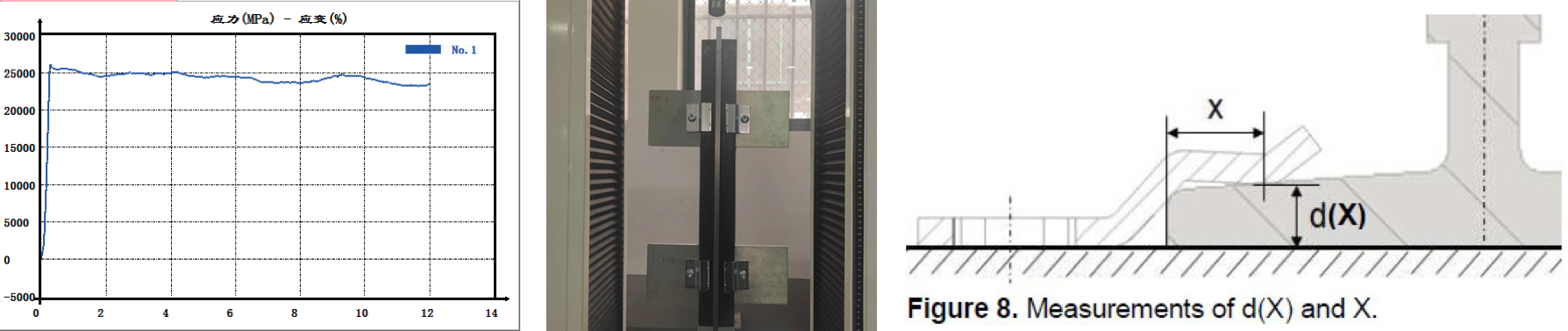

2. Rail clamping force

Features

• Stamping is used to replace hot forging and die-casting processes, which greatly improves production efficiency, reduces energy consumption and costs, and ensures stable and reliable quality;

• Unique process design prevents bending cracks and stress concentration;

• Square hole design with corresponding square neck bolts for quick and easy installation;

• Meets the friction requirements of GB7588-2020 standard

Application

• Fix the elevator car on the guide rail to prevent the car from shaking or derailing

Material, coating | Electrogalvanizing, |

Hole settings | Square hole/hexagon head bolt |

Certification/Test Report | Pass the friction/clamping force test |

Quality Inspection | Pass |

Product Origin | Songjiang District, Shanghai |

1. Friction test

2. Rail clamping force