| Availability: | |

|---|---|

| Quantity: | |

Features

The rope assembly device includes a screw rod, and a nut, a compression spring, a rope bowl (seat), etc. are set in order from top to bottom at the upper end of the screw rod. The upper end of the spring is supported in the rope bowl, and the lower end is supported in the rope bowl. The flat pad makes the whole device more stable. A wedge sleeve is extended from the lower end of the screw rod. The wedge block is placed in the cavity of the cone sleeve. The traction rope is connected with the cone core of the cone sleeve. The whole device is reduced in size and more stable. Professional welding design, more stable product performance, fully automated welding rope assembly production line, quality assurance

Product performance

• Bearing capacity: ≥80% of the designed breaking load of the wire rope

• Certified by the National Elevator Quality Supervision and Inspection Center

• 5.5 million fatigue tests

• CWB welding quality management system·IS05817 weld grade certification

Application

• Used for connecting the elevator traction rope and car, symmetrical device and machine room load-bearing beam

Product Features

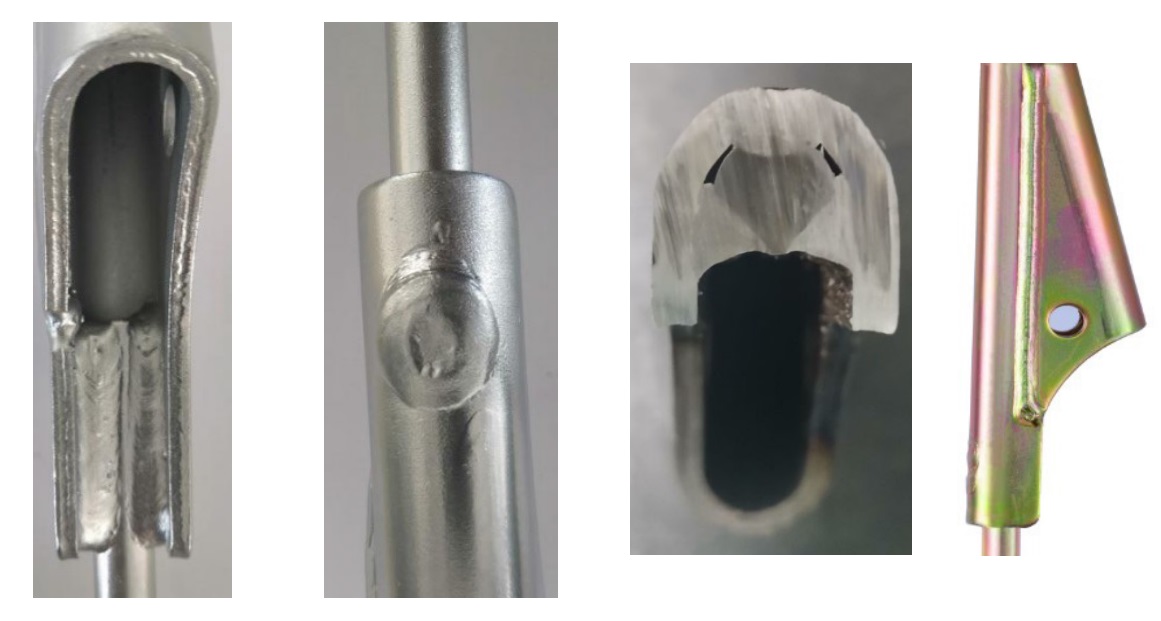

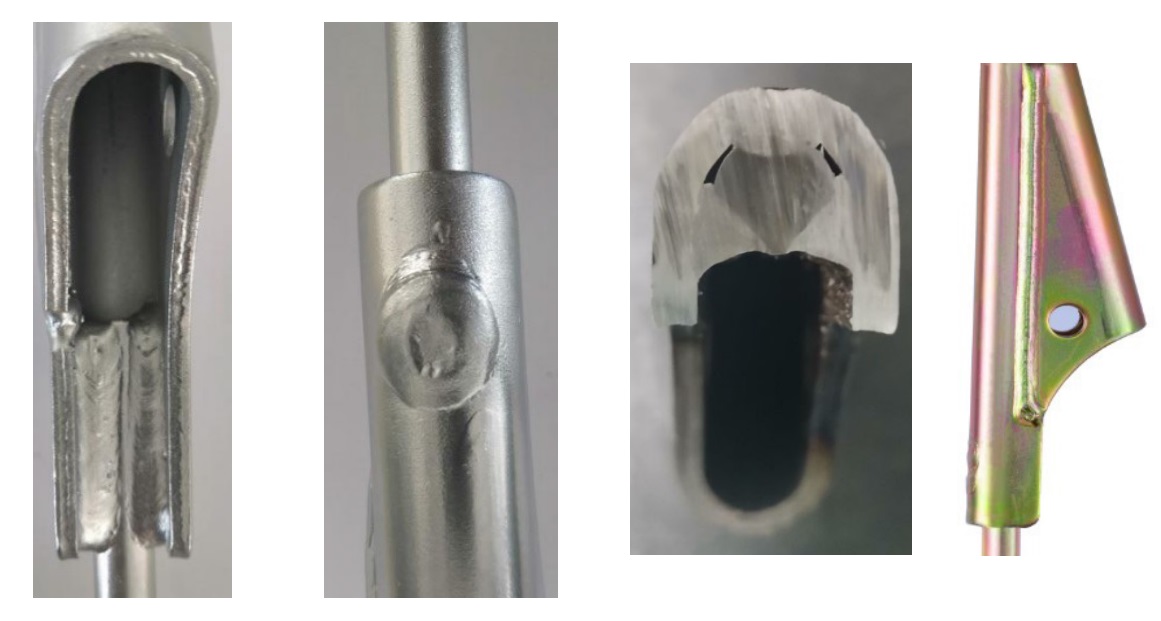

1. Round and short track welds

① Short track lengthened weld design to increase tensile load

The force points of the rope head wedge sleeve and the pull rod are changed from 2 to 3, which increases the safety factor and effectively improves each point

② After adding round track plug welding, the anti-fatigue ability;

③ After adding round track plug welding, the symmetry of the pull rod and the wedge sleeve can be better guaranteed, and the installation straightness of the wire rope can be better matched 4) The macroscopic corrosion of the section clearly observed that all three welds were in an effective fusion state

2. Long track groove welding

① Long track groove welding avoids the stress concentration area after bending, reducing the influence of bending stress on the performance of the product;

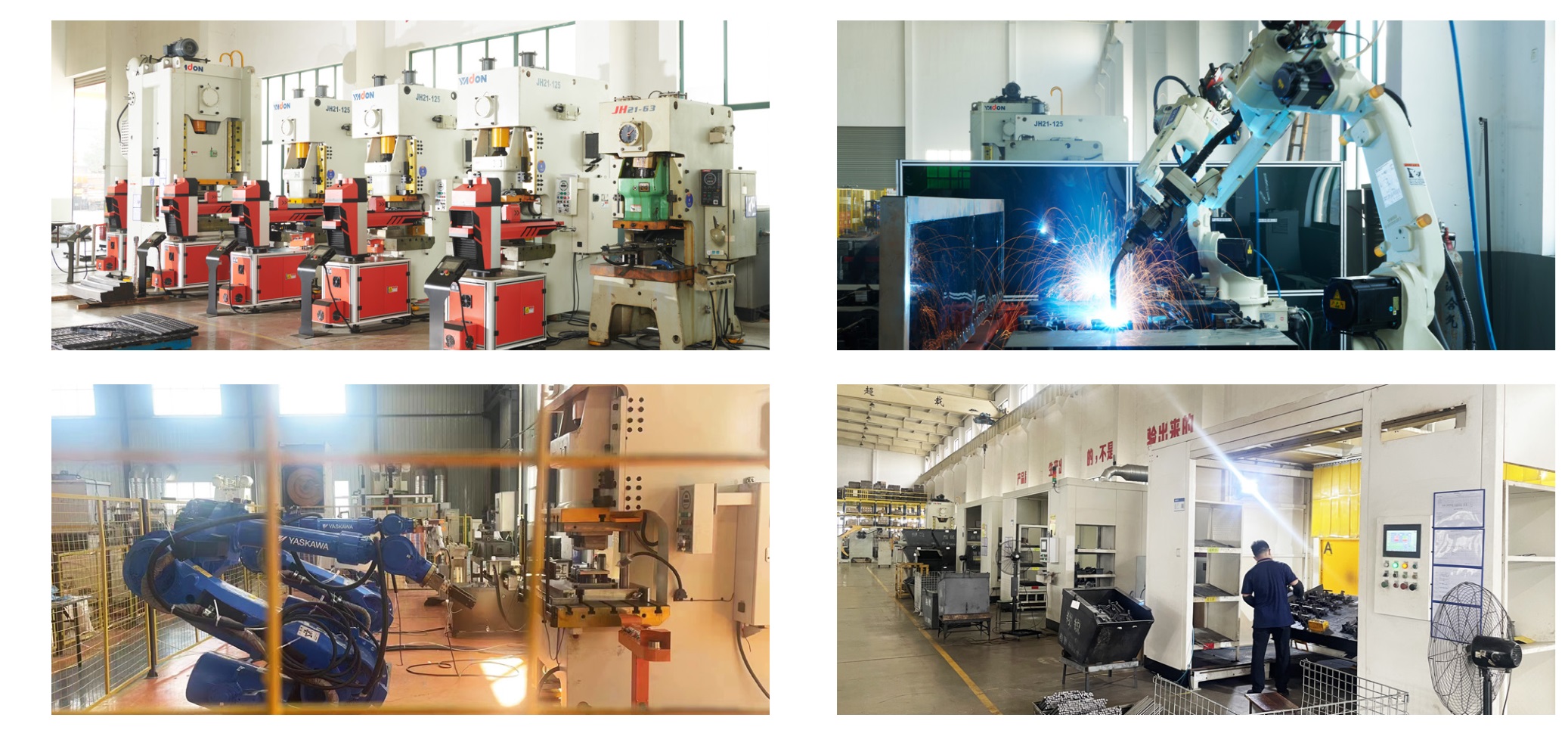

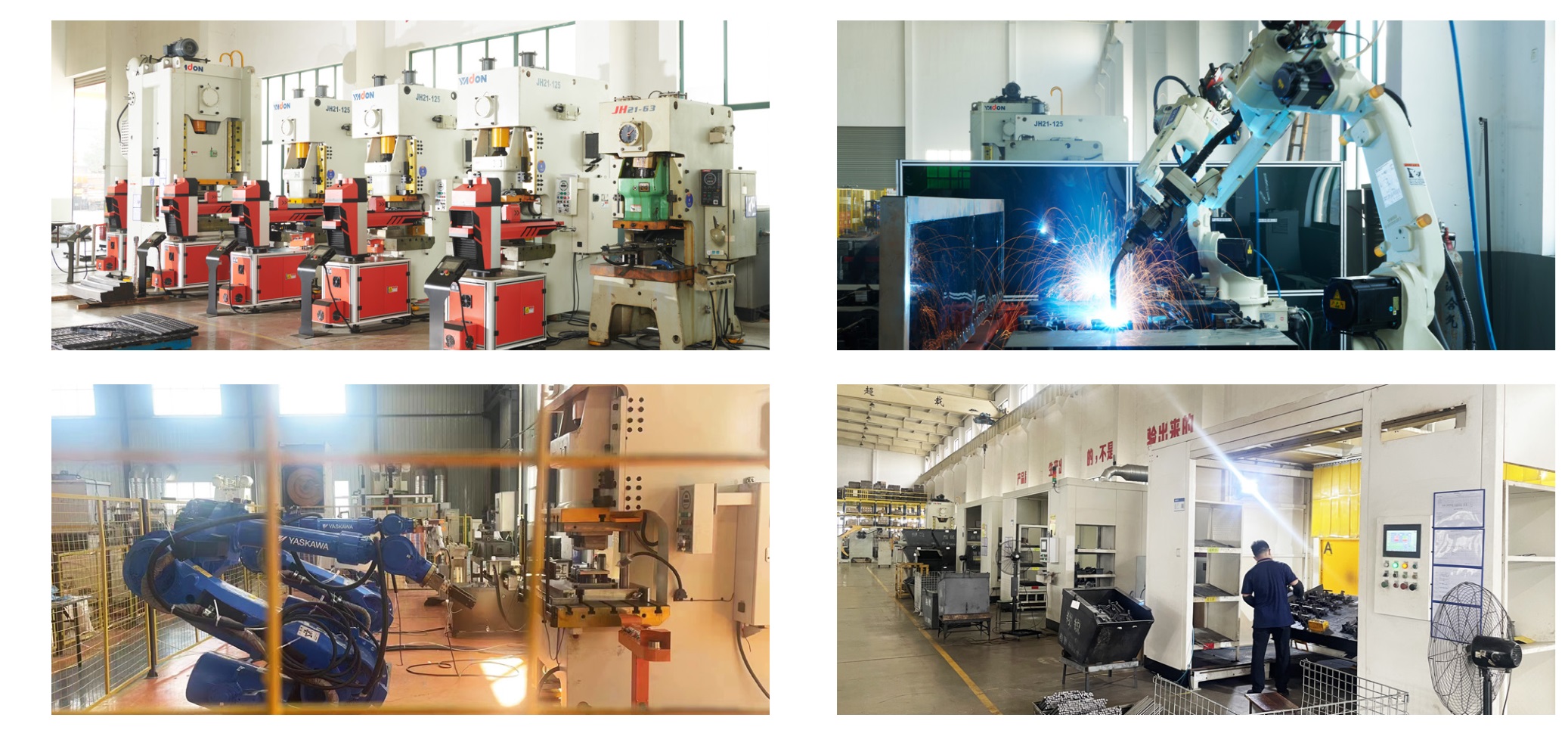

Equipment and production management

1. Welding

a. Obtained Canadian CWB welding system certification, welding managers and welders are all in accordance with the welding system b. Use Japanese OTC welding robot for automated welding

2. Wedge sleeve production

a. Use fully automatic precision punching machine with manipulator for production

b. Exclusive mold design, effectively reducing material bending stress

3. Tie rod production

a. Use fully automatic manipulator for production

b. Hot header integrated molding production line

c. Automatic temperature control monitoring system

Material, coating | Electro-galvanized, Dacromet, electrophoretic black (compression spring) |

Head setting | External thread |

Certification/Test Report | CWB、ISO5817、5.5 million times fatigue test, certified by National Elevator Quality Testing Center |

Flaw detection | X-ray/Magnetic Particle |

Quality Inspection | pass |

Product origion | Songjiang,Shanghai |

Features

The rope assembly device includes a screw rod, and a nut, a compression spring, a rope bowl (seat), etc. are set in order from top to bottom at the upper end of the screw rod. The upper end of the spring is supported in the rope bowl, and the lower end is supported in the rope bowl. The flat pad makes the whole device more stable. A wedge sleeve is extended from the lower end of the screw rod. The wedge block is placed in the cavity of the cone sleeve. The traction rope is connected with the cone core of the cone sleeve. The whole device is reduced in size and more stable. Professional welding design, more stable product performance, fully automated welding rope assembly production line, quality assurance

Product performance

• Bearing capacity: ≥80% of the designed breaking load of the wire rope

• Certified by the National Elevator Quality Supervision and Inspection Center

• 5.5 million fatigue tests

• CWB welding quality management system·IS05817 weld grade certification

Application

• Used for connecting the elevator traction rope and car, symmetrical device and machine room load-bearing beam

Product Features

1. Round and short track welds

① Short track lengthened weld design to increase tensile load

The force points of the rope head wedge sleeve and the pull rod are changed from 2 to 3, which increases the safety factor and effectively improves each point

② After adding round track plug welding, the anti-fatigue ability;

③ After adding round track plug welding, the symmetry of the pull rod and the wedge sleeve can be better guaranteed, and the installation straightness of the wire rope can be better matched 4) The macroscopic corrosion of the section clearly observed that all three welds were in an effective fusion state

2. Long track groove welding

① Long track groove welding avoids the stress concentration area after bending, reducing the influence of bending stress on the performance of the product;

Equipment and production management

1. Welding

a. Obtained Canadian CWB welding system certification, welding managers and welders are all in accordance with the welding system b. Use Japanese OTC welding robot for automated welding

2. Wedge sleeve production

a. Use fully automatic precision punching machine with manipulator for production

b. Exclusive mold design, effectively reducing material bending stress

3. Tie rod production

a. Use fully automatic manipulator for production

b. Hot header integrated molding production line

c. Automatic temperature control monitoring system

Material, coating | Electro-galvanized, Dacromet, electrophoretic black (compression spring) |

Head setting | External thread |

Certification/Test Report | CWB、ISO5817、5.5 million times fatigue test, certified by National Elevator Quality Testing Center |

Flaw detection | X-ray/Magnetic Particle |

Quality Inspection | pass |

Product origion | Songjiang,Shanghai |